6 Best Models for Testing Your 3D Printer

If you just received your 3D printer, or are looking forward to 3D printing an intricate design, it’s important to start with a test print. That way, you’ll be able to see what your printer is and if it’s the next printer. best 3d printer You can avoid wasting time and materials on projects that don’t work, whether they work or not.

A test print allows you to analyze how your printer handles overhangs, holes and supports, and learn what settings such as temperature, speed, layer height and shrinkage work best for your 3D printer and filament. You can also use a test print to check the speed of fast printers. Any model can be used to test a printer, but there are some models specifically designed for that purpose. Below, we have selected six test models that are ideal for 3D printing.

1. 3D bench

The 3D Benchy is one of the most popular benchmark designs you can use to test the capabilities of your 3D printer. Originally created by Creative Tools, available at: 3D Benchy official websiteVarious STL file sharing websites are listed here, such as Thingiverse, Printables, Cults3D, etc. Clicking on any of these websites will take you to that website.

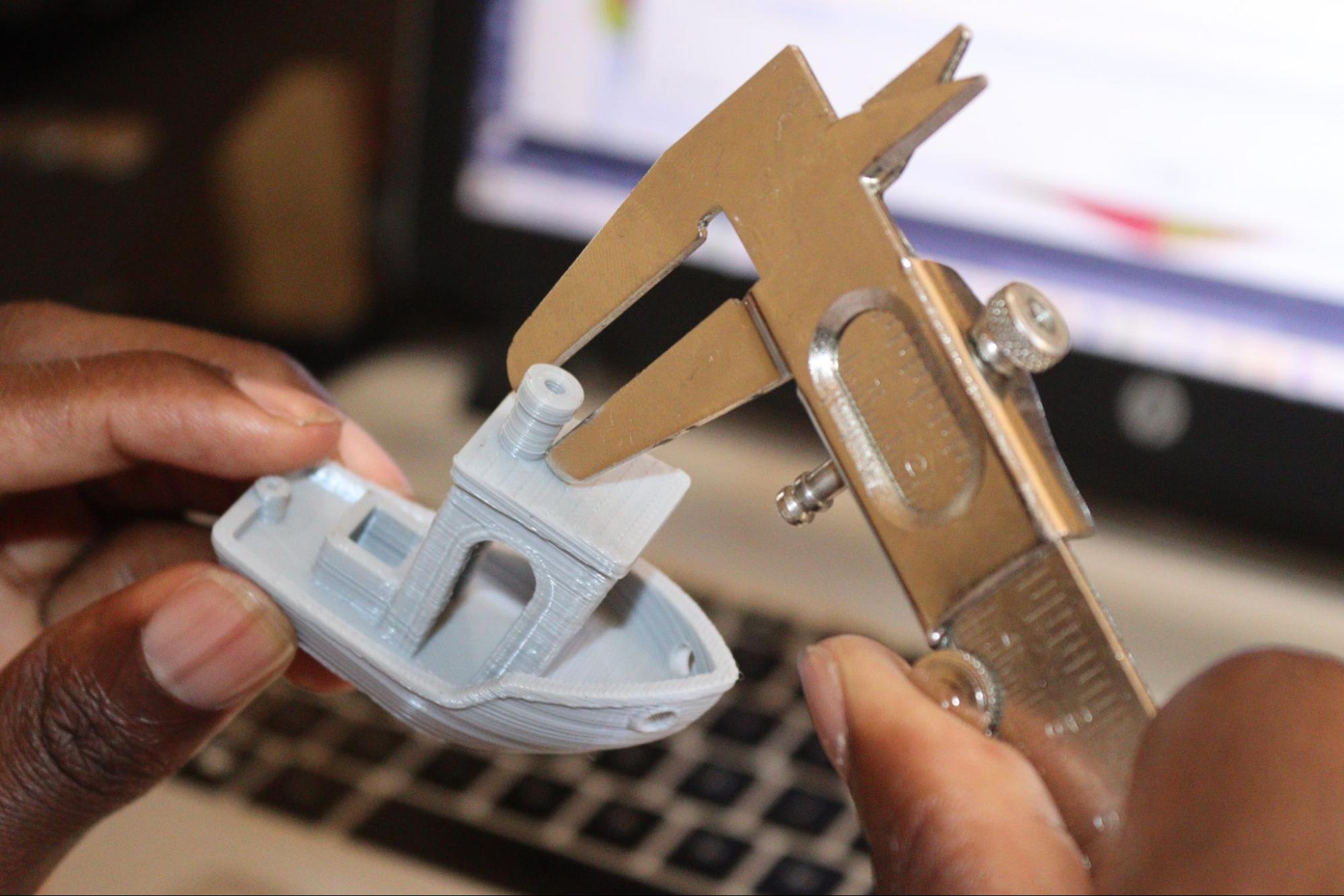

If you download the file from the official website, you need to print it as is (same size) without any settings. The intricate nature of the design makes it an excellent print for troubleshooting and adjusting machines. In addition to its small size, it has overhangs at various angles to test how a 3D printer handles the bridge.

In addition, circular holes, rectangular windows, and each section of the design on the model have specific sizes (see illustration). Pamphlet), you need to measure the model after 3D printing to see how accurate the 3D printer is.

You can also test how your 3D printer controls temperature and cooling by checking the overall quality of the print, whether the surface is smooth, rough or dirty. To fix the problem, you need to adjust the slicer settings.

A small hole protruding from the inside to the top and a wheel-like shape are essential for testing how the machine handles fine details and intricate designs. If your 3D printer is set up correctly, these sections will print well, but if there are issues, the holes may be smaller than expected.

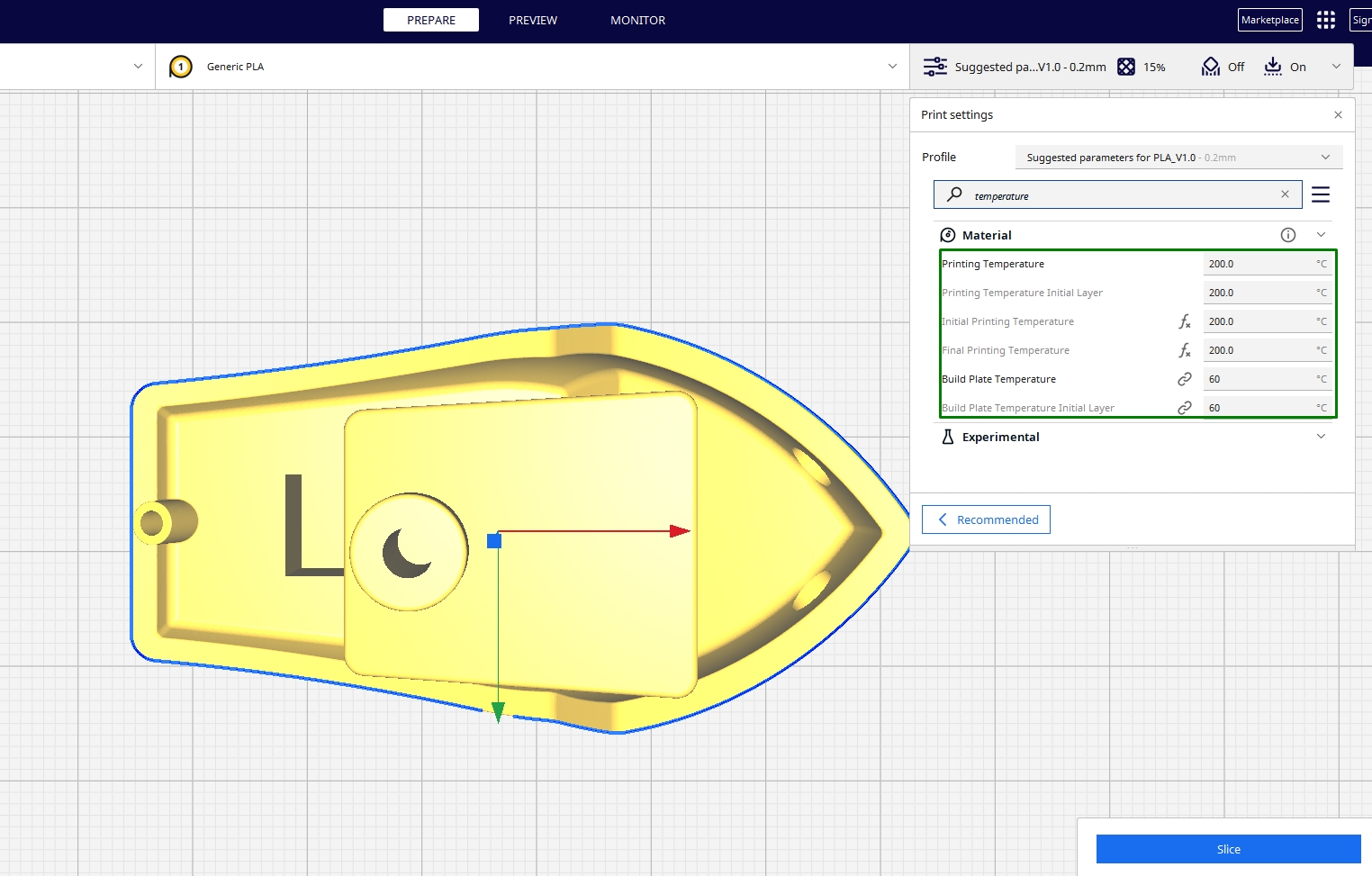

You should check the 3D Slicer hole settings to see if the holes are covered or not well visible. For example, unchecking remove all holes Cura’s options prevent holes from being removed.

2. Calibration cube

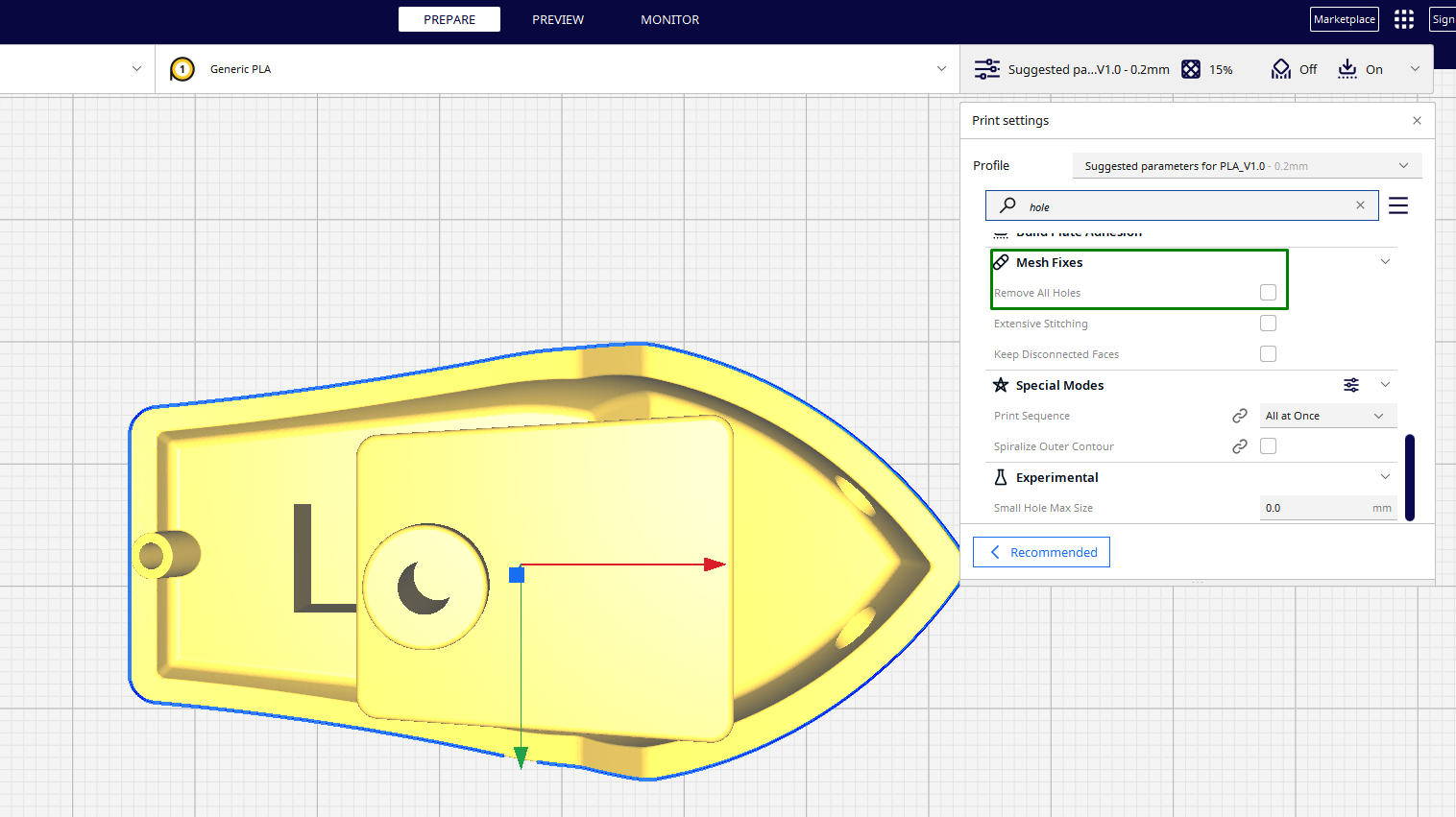

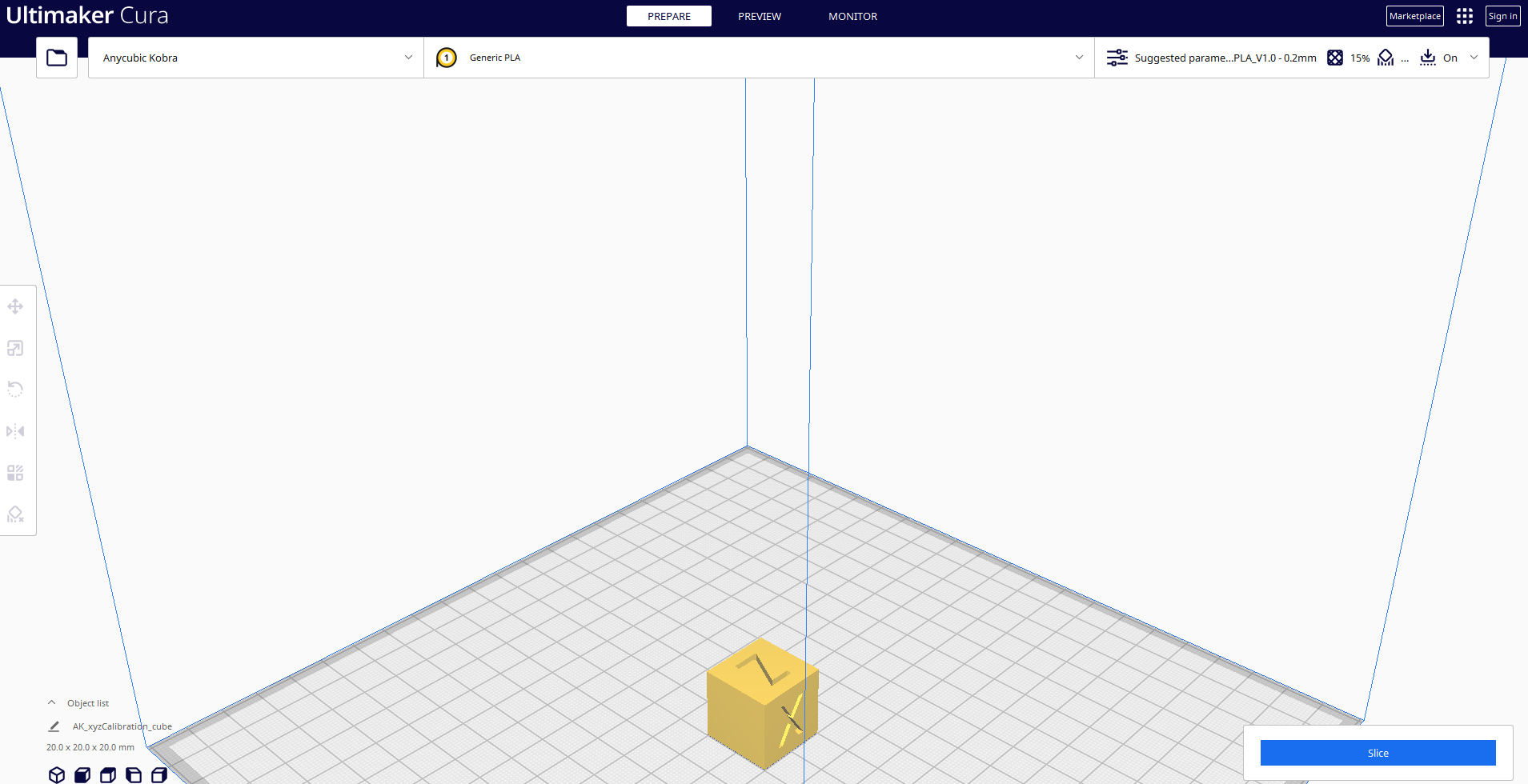

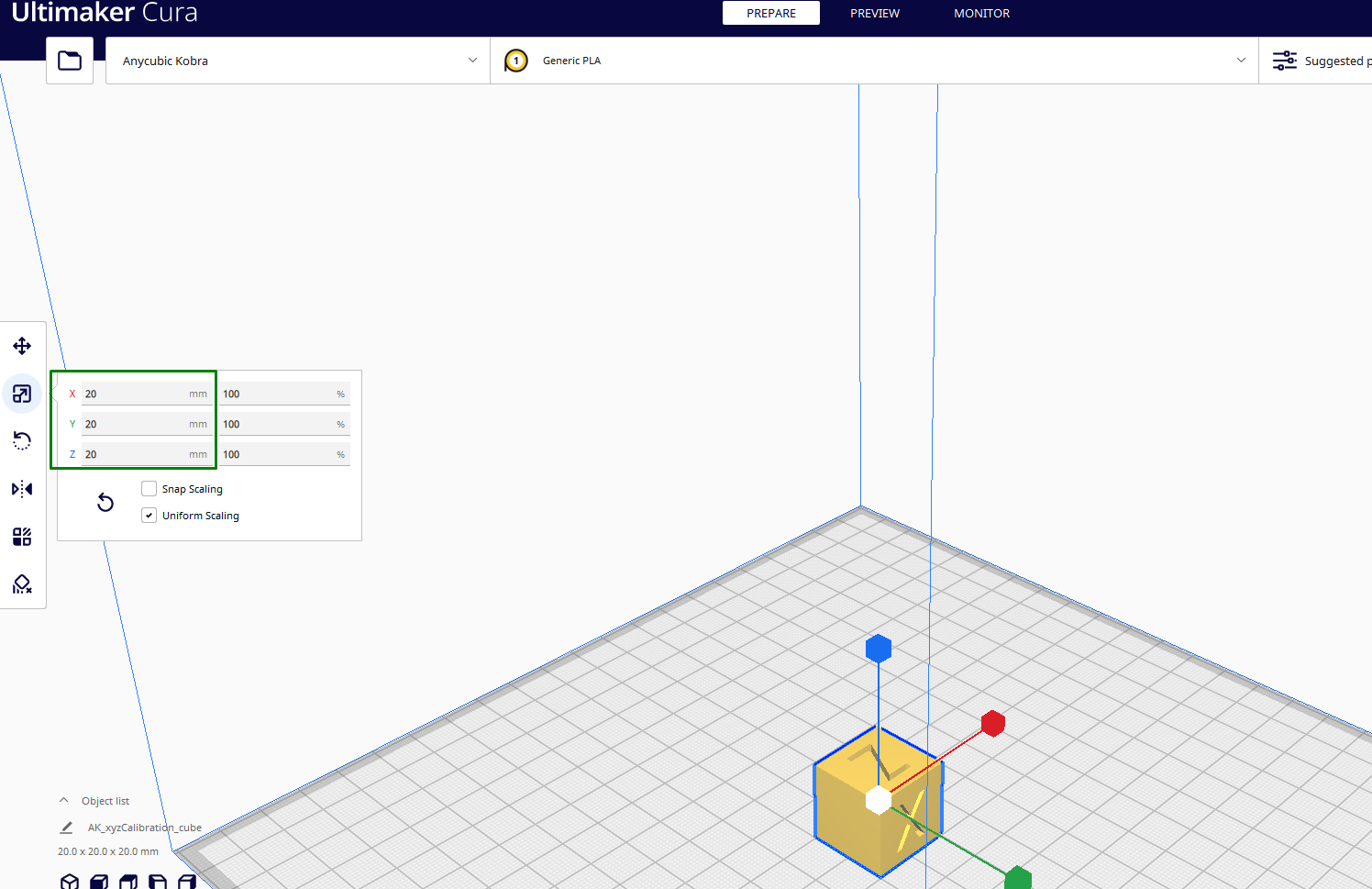

of XYZ calibration cube It helps to adjust the dimensional accuracy of the 3D printer. The dimensions are precise, such as 20mm on each side. After printing, the dimensions should be measured using vernier calipers or other measuring tools to ensure the intended size. This will give you an idea of how accurately the stepper motor is moving. If the size of your print is far from the size of your digital file, this is an important test print that should be used to troubleshoot any issues.

To print this model, you need to properly orient it within the Slicer and make sure the letters are parallel to the axis you are measuring, as shown below.

In most cases the model will be imported with the correct orientation. After 3D printing, measure 3 sides and note the values.

Then you can compare the length, width and height values of the slicer to see if they are within the same range.

If the sizes are significantly different, you’ll need to fine-tune your machine until you’re roughly in that range. Not only does it help you know if your machine is tuned properly, it also helps identify problems related to under or over extrusion or even steps per millimeter.

3. All-in-one 3D printer testing

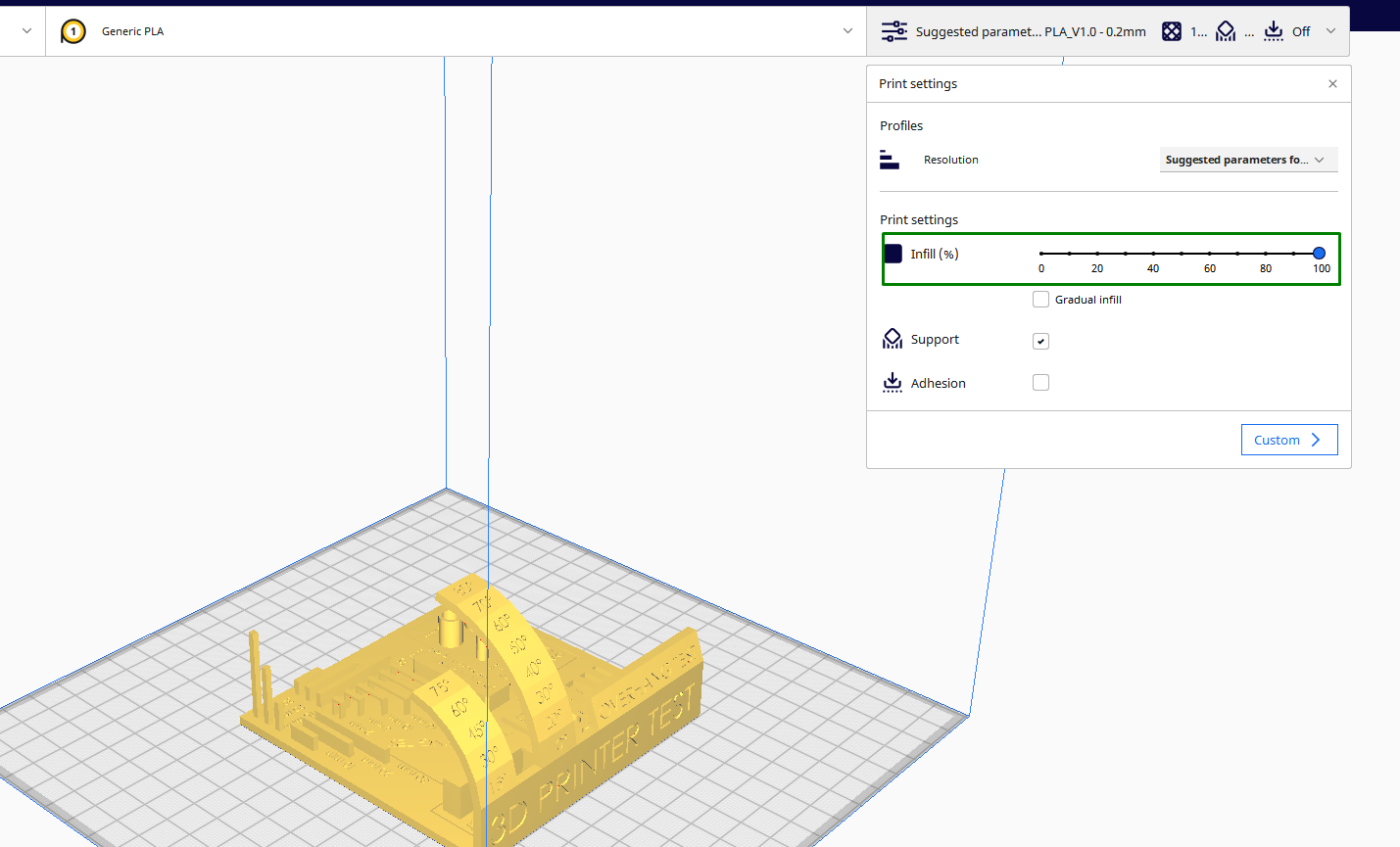

As the name suggests, All-in-one 3D printer tesFrom overhangs, supports, hole tests, temperatures, and even bridges, test how your 3D printer handles different designs. After downloading and slicing the file, the designer suggests using her 100% infill without support.

After 3D printing, we need to examine all parts of the model to see how the machine handles them. You can identify if there is a problem with any part and see what action to take.

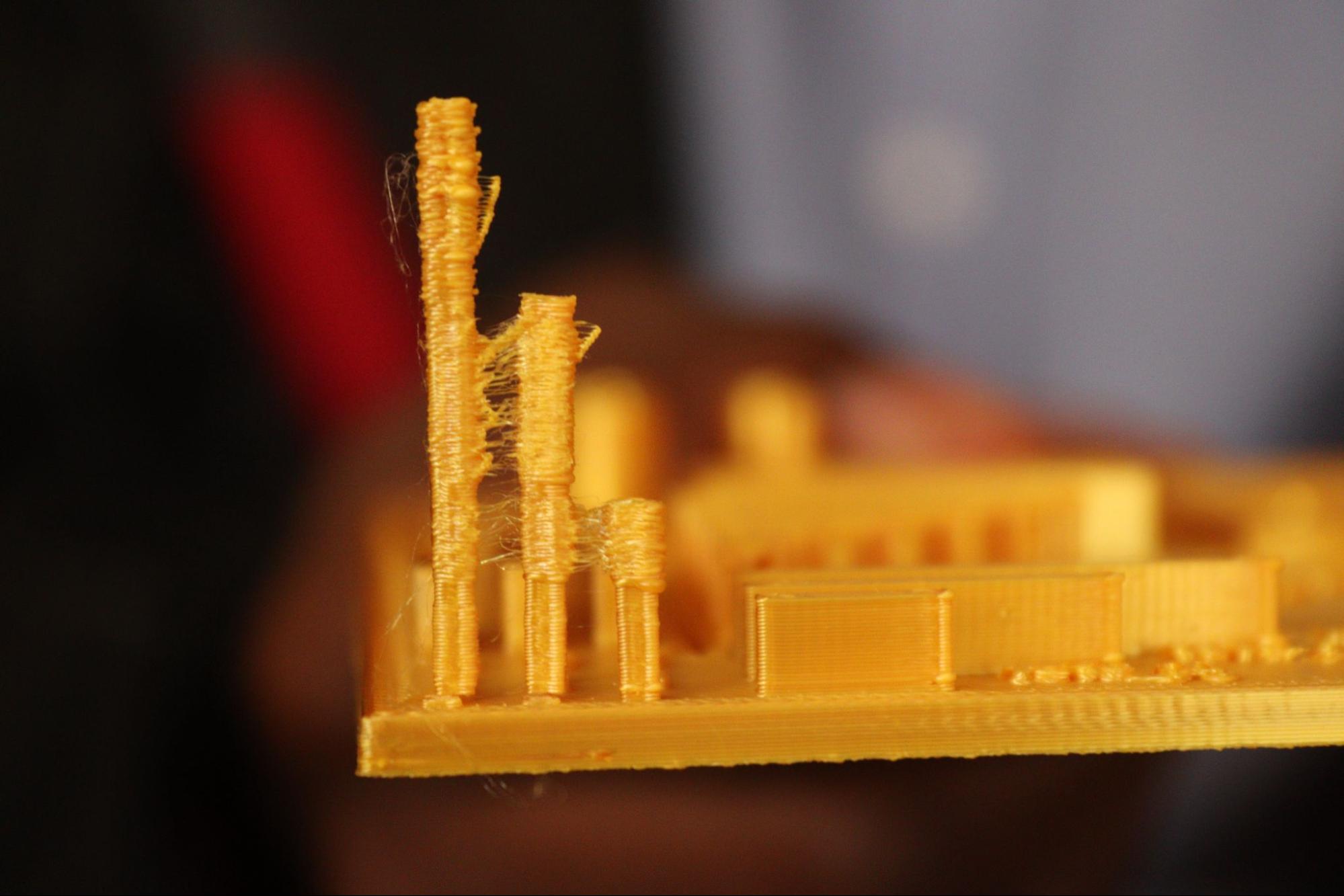

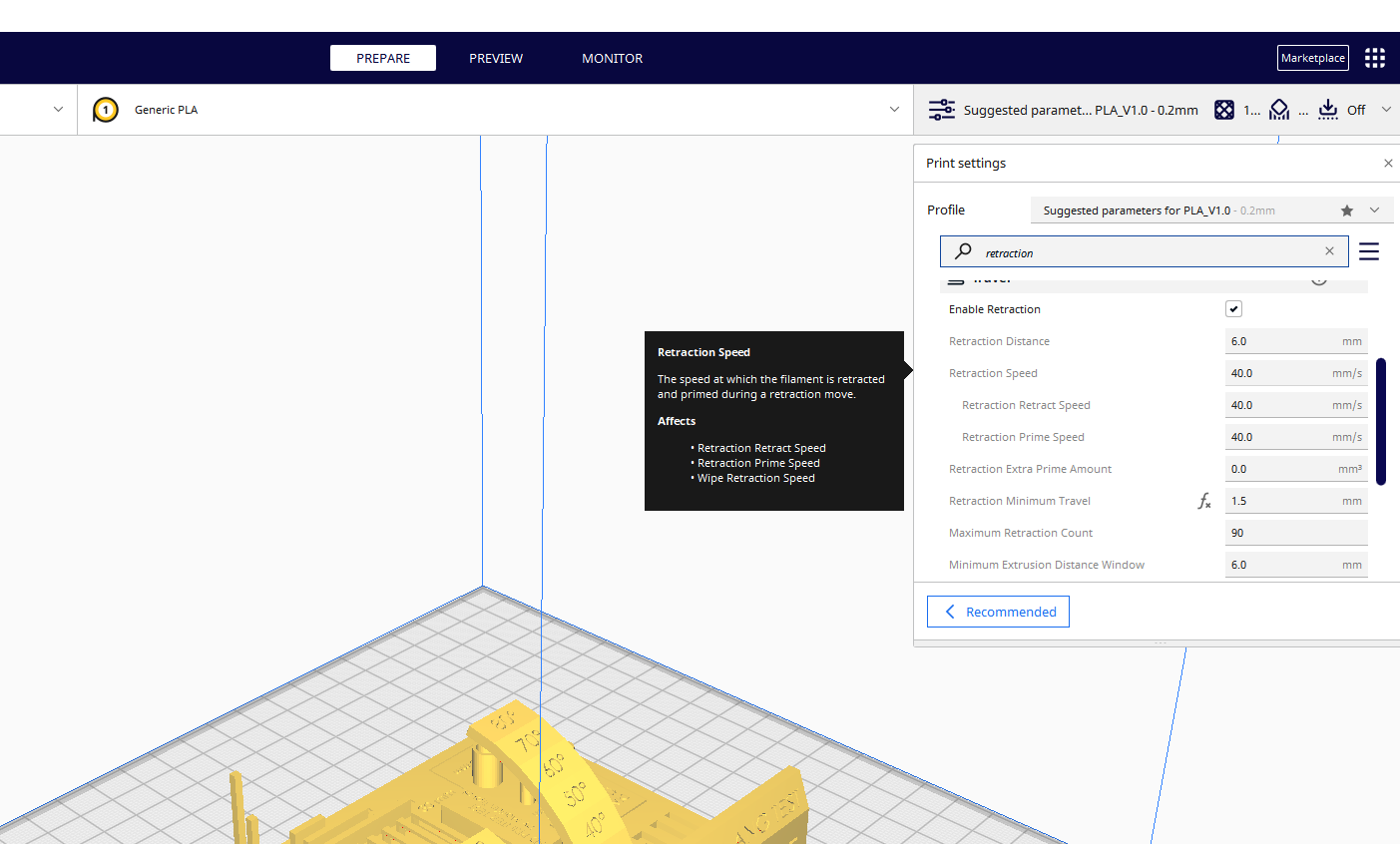

For example, in my case I saw stringiness in some sections of the design. This means that the retraction and temperature settings need to be adjusted to fix the problem.

This print will also help you understand how the holes and walls of your design will be 3D printed. You can also change speed, temperature, and other settings to make sure your print is accurate.

4. Retraction test

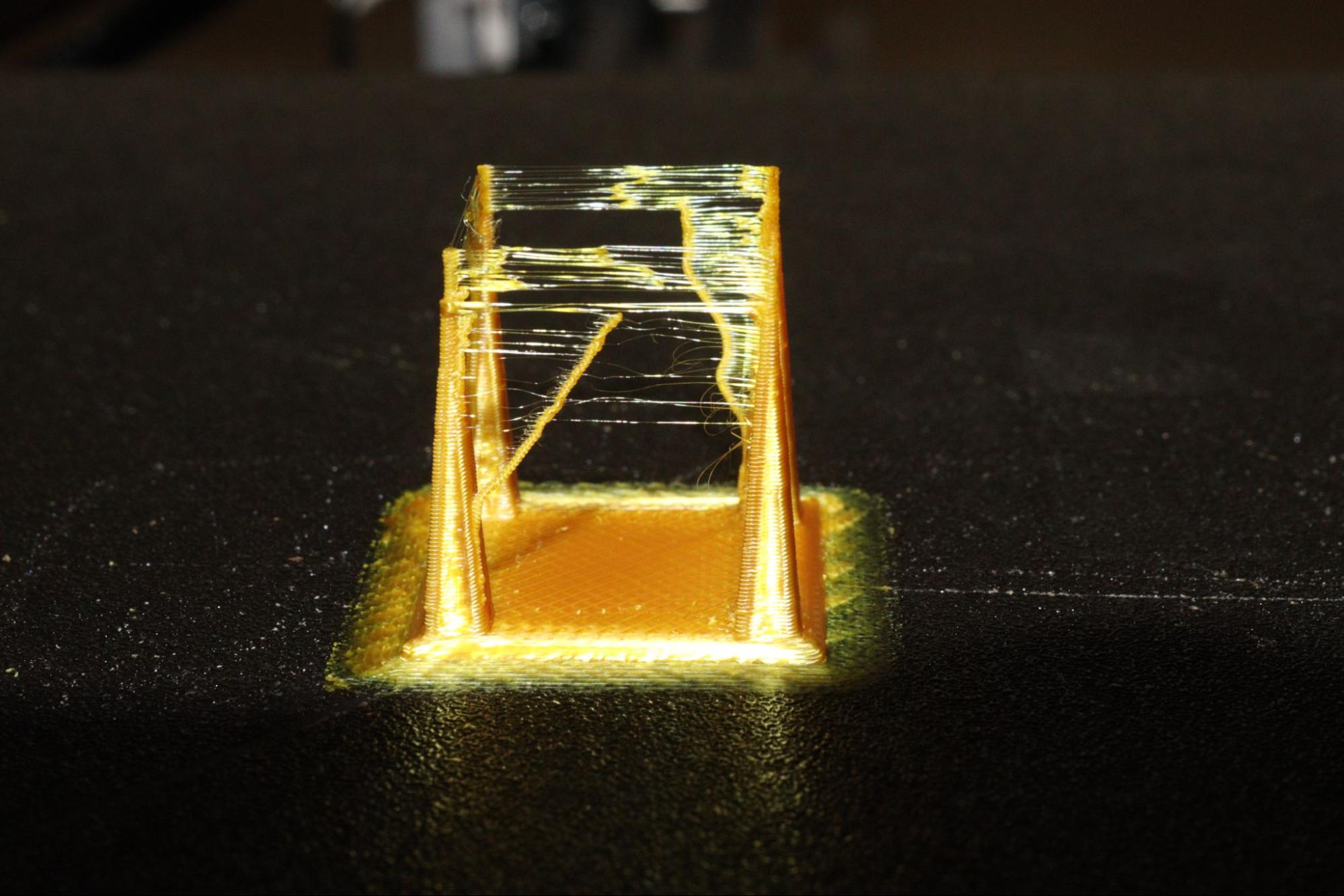

of shrinkage test The model is useful for testing how the filament pulls and pulls back into the nozzle as the 3D printer moves from one end to the other. If the retraction setting is not set correctly, the thread may be stretched. Strings are where strands of fine filament build up on your design, as shown below.

If you experience stringiness, you will need to adjust the shrinkage speed of the slicer. In most cases, this value should be slightly higher so that the filament retracts quickly and does not stick out when the print head moves.

If the thread still comes out even if the winding speed is increased, it is possible to increase the winding distance. In my case, just increasing the speed had some effect on the tip of the tower, but I got through it without much trouble.

5. Smart Compact Temperature Calibration Tower

Smart compact temperature calibration tower Useful for calibrating 3D printers and filaments. This allows you to evaluate print quality at different temperatures and determine the ideal temperature range for your filament. Temperature segments in the design gradually increase, making it easier to understand how each section was 3D printed.

The designer recommends printing with 15% infill and 0.2 mm resolution, and no supports. Analyze your design after 3D printing and adjust temperature settings accordingly.

6. Flow rate calibration print

Flow calibration print This is another test print to help you adjust the flow rate of your 3D printer. Flow rate is the speed at which the extruder pushes the filament out of the nozzle and is measured in millimeters per second. Affects print quality and print speed. A lower flow rate will slow down and produce a finer detail print. On the other hand, a higher rate will reduce 3D printing time, but too high a rate can cause problems such as overextrusion.

If you experience issues such as bleeding, overextrusion, or poor print quality, it is important to 3D print this test model and use it to troubleshoot the issue.

Above are just a few of the many test prints available. If you know the problem you want to troubleshoot, you can choose an appropriate design and use it for testing. However, if you want a general overview of different aspects of the machine, you can start with a simple cube, progress to more complex designs such as a 3D bench, and then test an all-in-one 3D printer that covers it all. Most of these only take a few minutes to a few hours to print, so you’re not wasting your time or materials.

more: best 3d printer

more: Best budget 3D printing

more: best resin 3d printer