Kingroon KP3S Review: Tiny King of the Direct Drive

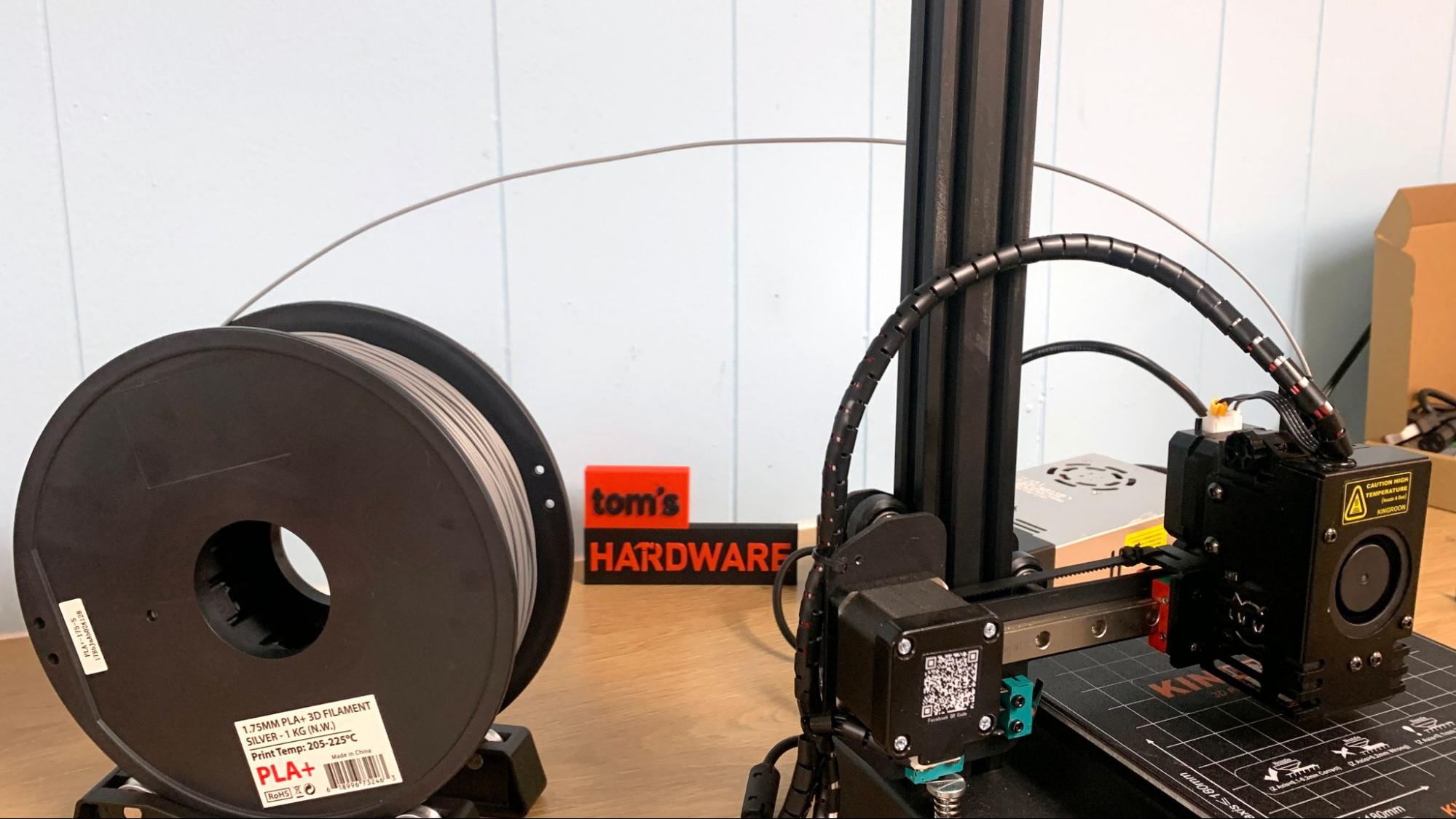

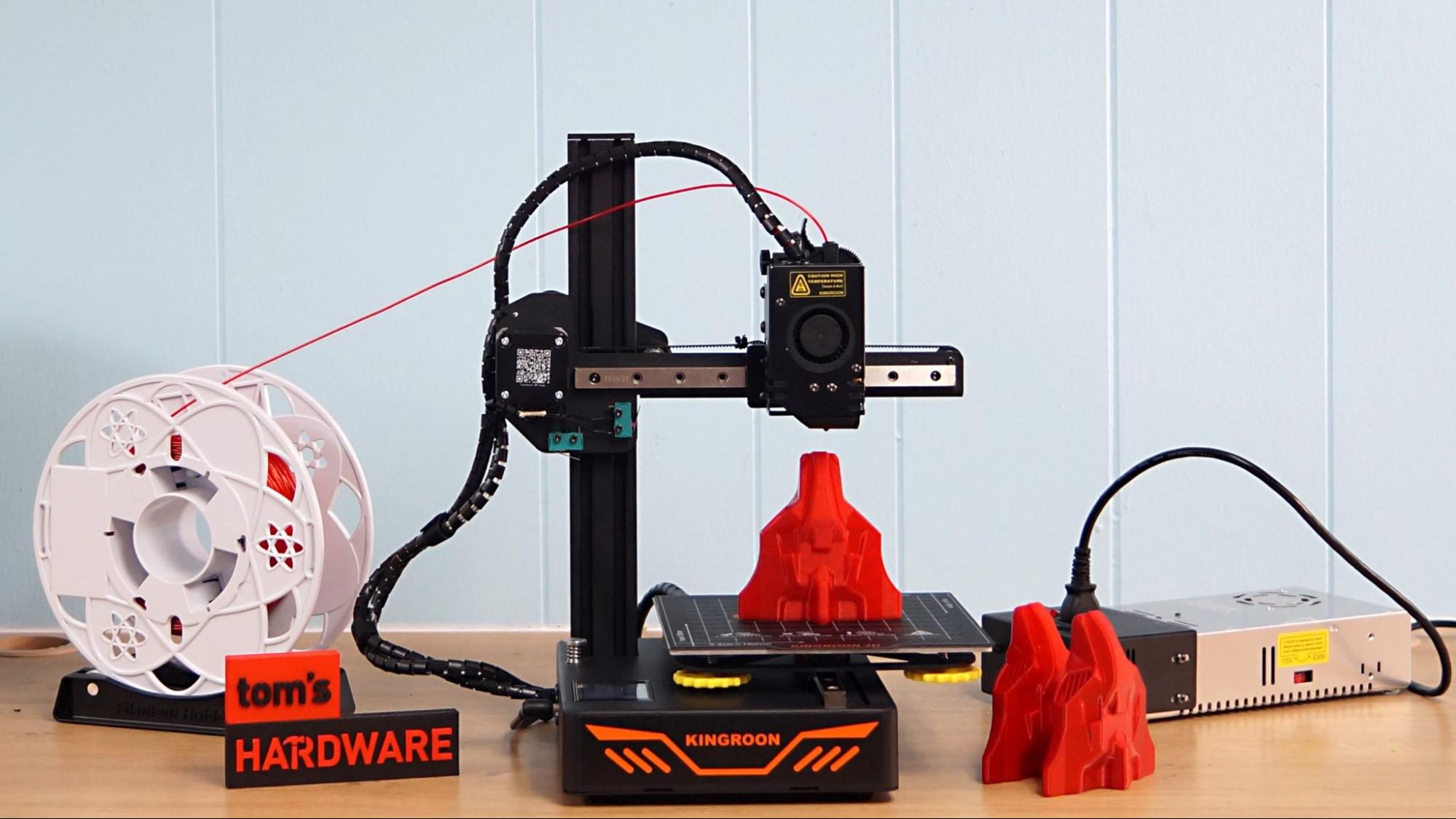

Kingroon KP3S is a tricky little 3D printer. It’s small, inexpensive, and relatively easy to set up, making it perfect for beginners. But he’s a printer, power supply, and tabletop spool holder spread across three units, so it’s a mess. Many pictures of the KP3S omit the power supply or spool holder, or sometimes both, in an attempt to make it look like a portable machine. Not unless you put it in a box.

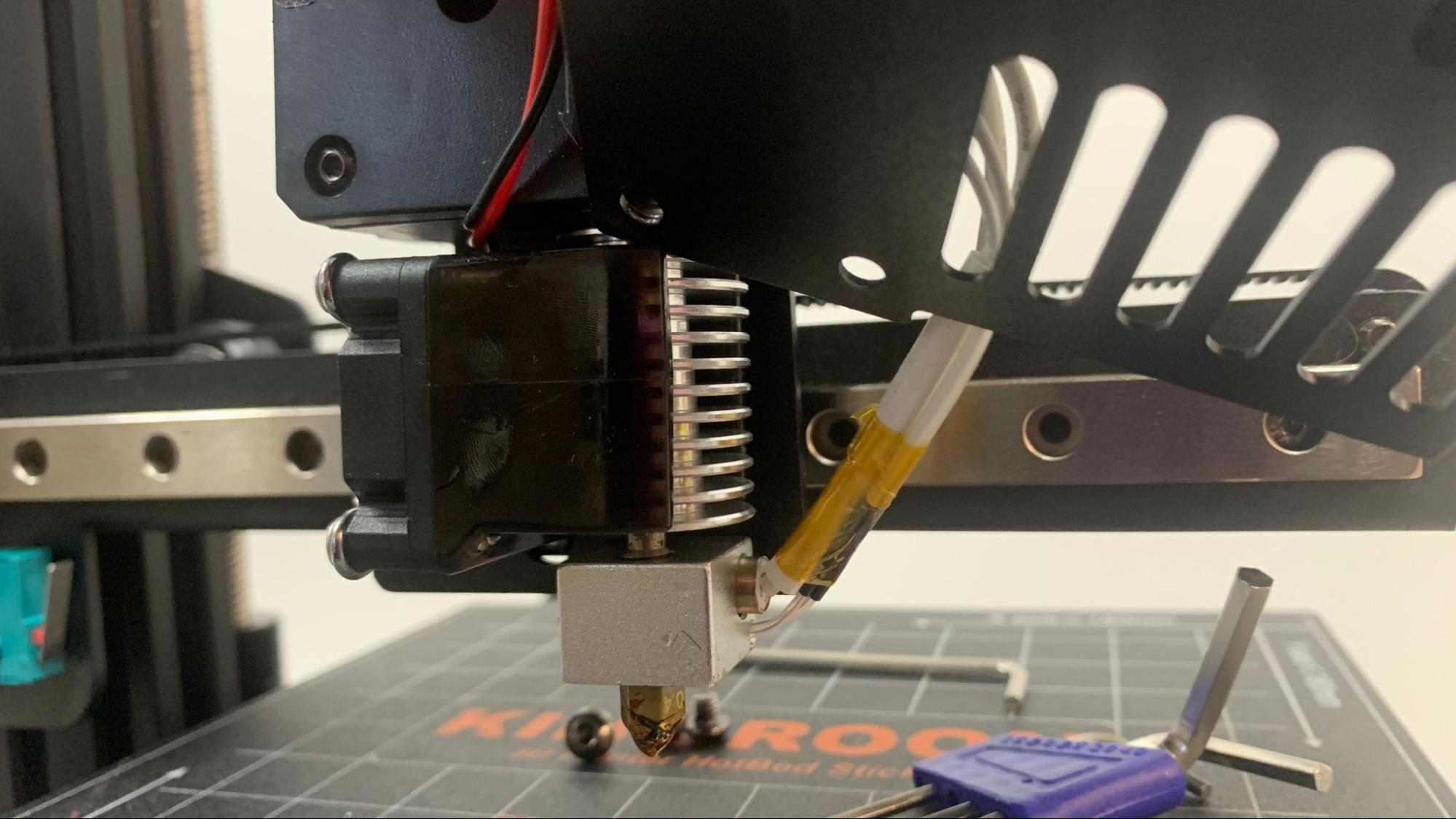

Thanks to the Titan clone extruder with a gear ratio of 3 to 1, this machine prints very well. Using common parts means you can easily upgrade this machine if you want to add an all metal heat break or buy a nozzle from Amazon.

The smaller KP3S isn’t for everyone, but with a retail price of $169, it’s a good choice if you’re trying 3D printing for the first time or just want a cheap, reliable second printer.

Specifications: Kingron KP3S

| build volume | 180 x 180 x 180 mm (7 x 7 x 7 inches) |

| material | PLA/PETG/TPU/ABS (up to 260 degrees) |

| Extruder type | direct drive |

| nozzle | .4mm MK8 |

| build platform | PC coated flex sheet, heated |

| bed leveling | manual |

| filament runout sensor | No |

| connectivity | microSD card, USB Type A |

| interface | 2.5 inch color LCD touch panel |

| machine footprint | 400 x 390 x 370 mm (15.7 x 15.3 x 14.5 inches) |

| machine weight | 6 kg (13.2 lbs) |

Included items: Kingroon KP3S

Kingroon KP3S comes with everything you need to get started, including tools to assemble and maintain the printer and side cutter. We also have 1 spare nozzle, 1 spare thermistor and small samples of PLA available.

There is a paper booklet with a quick start guide to help you build your printer. Some sample prints are provided on a microSD card, as well as a copy of Ultimaker Cure 4.9.1 and Kingroon’s custom slicer.

We also received 3 additional nozzles of various sizes for testing. They don’t appear to be part of the standard kit.

Assembling the Kingroon KP3S

Kingroon KP3S arrives mostly pre-assembled. The upper gantry he is attached to the base with two bolts. The Z-axis rod is sold separately and must be inserted into the coupler and then screwed into the base.

There are no electronics to deal with as everything is pre-wired. The power supply is a separate unit and connects with a normal appliance cable. The spool holder is likewise separated and does not need to be assembled.

Kingroon KP3S Leveling

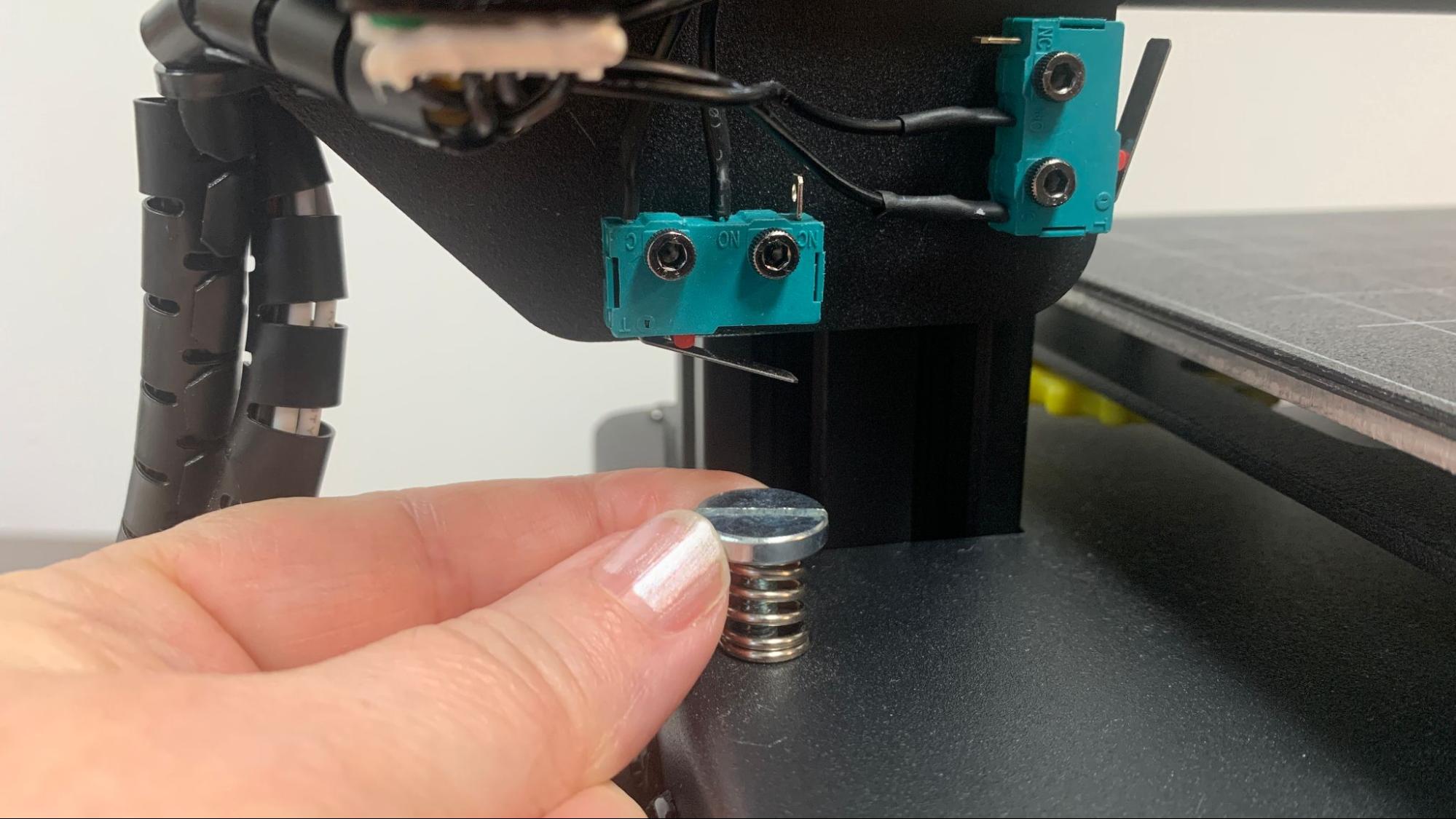

Kingroon KP3S needs to be leveled manually. The small size of the machine makes the knobs a bit harder to manage, especially since the left knuckle can hit the touchpad. This may be an issue for people with large hands. My hands are small for an adult, so I had to press the buttons all the time.

There is no control for changing the distance of the nozzle from the bed other than moving the Z stop screw which is rather difficult. This makes bed leveling important as the only way to change the Z-height while a print is running is to adjust the bed leveling knobs.

For this reason, we recommend leveling while the printer is warming up. We tested the KP3S leveling both hot and cold and found that the machine definitely swells when hot. Cold leveling kept the nozzle too far from the bed and the filament didn’t stick.

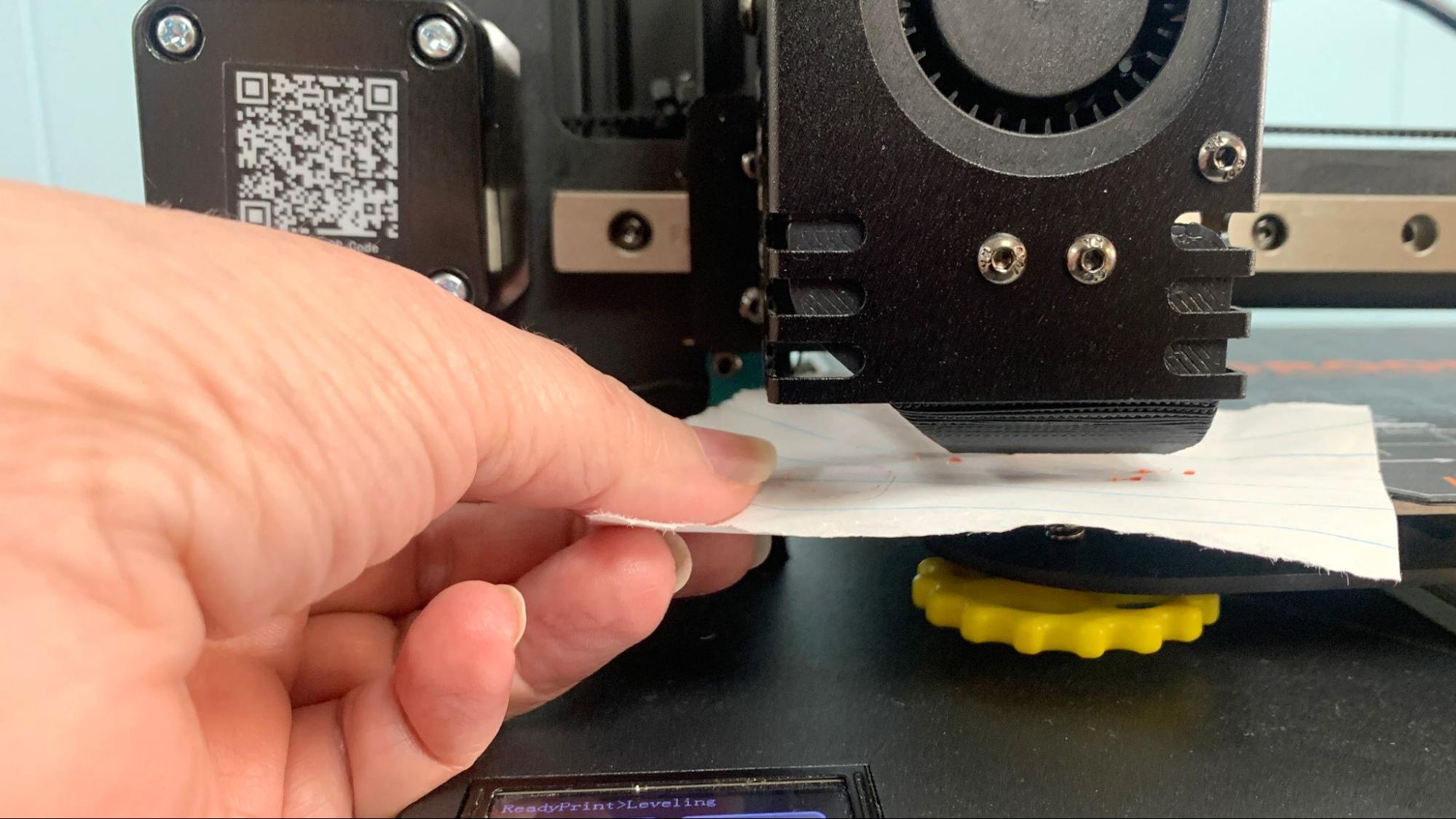

To level the machine, click Level on the control screen. You can choose from 5 points on the screen. Click in the corner of the screen to move the print head to Z height 0 on the bed. Place paper under the nozzle and twist the appropriate yellow knob to raise or lower the bed. I want to just rub the paper with the nozzle.

Do this for all four corners. Ideally, when the corners are level, the center point is also at an acceptable height. For more information on manual bed leveling, please see the following articles: How to manually level the bed of a 3D printer.

Loading filament on Kingroon KP3S

The Kingroon KP3S filament path is very easy and you can load the material without any hassle. There is no program for loading or removing filament, so you have to handle each step yourself.

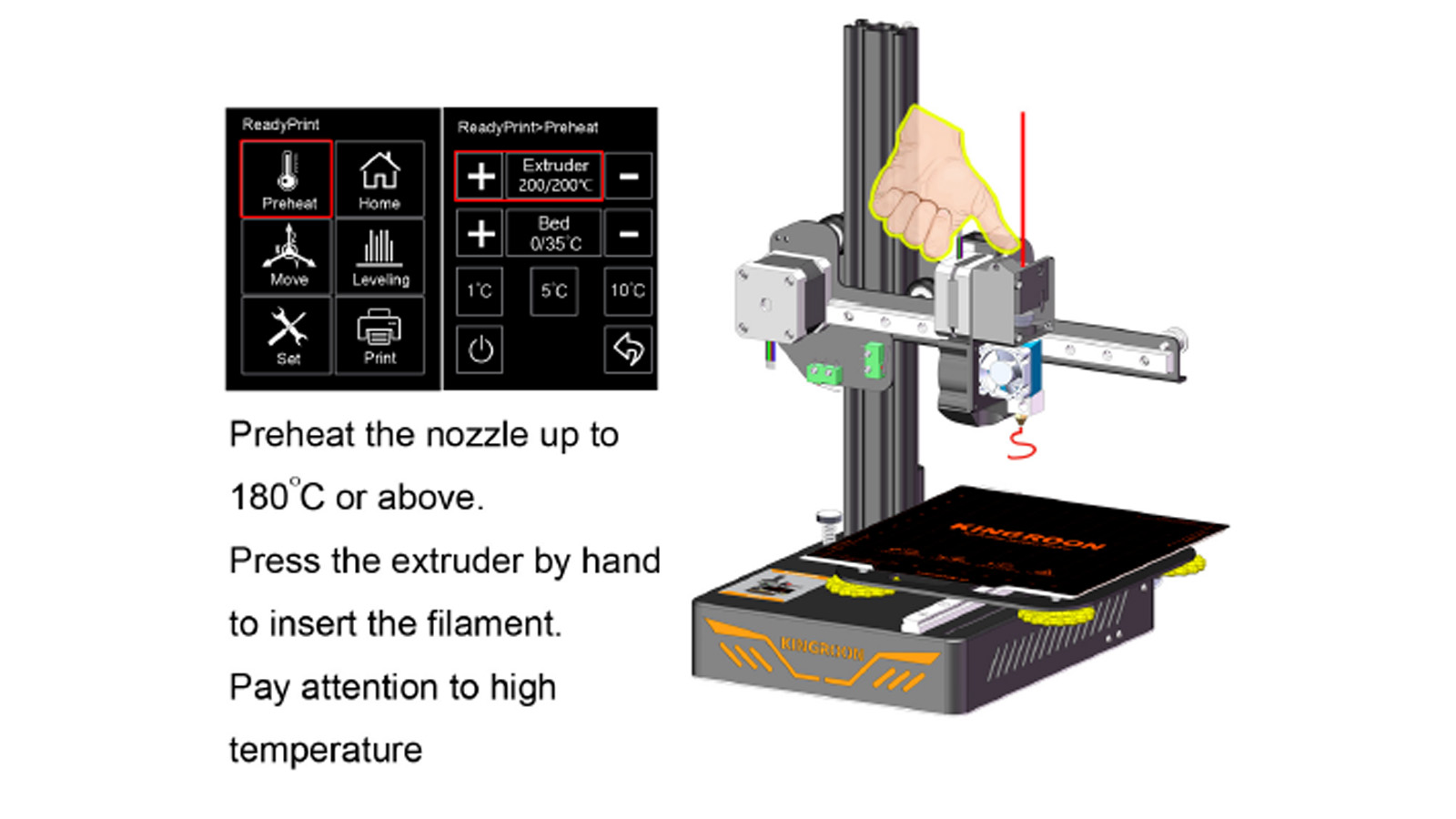

First, cut the filament diagonally and then insert it into the opening at the top of the extruder. Press the lever and push the filament in a few centimeters until it stops.

Select “Preheat” from the main menu.

Then tap the plus sign next to “Extruder” until the temperature exceeds 180 C. Once hot, tap the back arrow, then tap Move. Click on the extruder symbol and select “In” to advance the filament. Keep beating until the filament comes out of the nozzle.

To replace or remove filament, reverse the process.

Design of Kingroon KP3S

Kingroon KP3S is a cantilever style 3D printer. So everything is balanced on one Z-axis tower. A very quiet machine with quiet stepper drivers and a quiet fan. The direct drive has a large gear ratio of 3:1 and a Clone Titan style extruder that handles material very well. It also operates on linear rails, which are smoother and more precise than wheels.

The power supply is a separate unit not found on newer machines. The cord that connects the power supply to the body of the printer is fairly short, so your options for hiding that ugly brick are limited. An on/off switch is located on this segment of the printer.

Please note that the KP3S is the third release and is trying to lag behind the KP3S Pro.The new machine has a power supply at the base and is available now Pre-order for $209.

The KP3S has a small 2.5 inch color touch screen set on top of the base. The screen is pressure sensitive, so you can use the stylus to tap if the buttons are too small.

The spool holder is two separate rails with roller bearings that adjust to any size spool. Cardboard spools are nasty when used more than halfway. The spool needs some weight to stay in place and can easily be dislodged by the pulling motion.

The filament is also bent at severe angles when printing tall objects as the extruder rises higher.

These two issues – a separate power supply and a tabletop spool holder – can be addressed with the printable mods shared by the fellows. Makers of ThingiverseYou’ll find new spool holders and filament guide prints that can be attached to the tower, and a clever way to raise the machine to make room for the power supply to fit underneath.

The print bed, not my favorite, has a removable PC-coated surface that’s good for holding prints. Soft surfaces can be easily scratched, so be careful to gently remove the print by separating the bedding from the print rather than prying it open with a scraper.

A clever cheat sheet is printed on the print bed to remind the user of examples of the X and Y directions and the full Z height.

File/software preparation for Kingroon KP3S

Kingroon KP3S has its own custom slicer simply called KingRoon3D. This is a very easy-to-use program with quick, basic and expert modes, all tailored for KP3S.

There is also a profile included with Cura if you want to download the more popular slicers. There is no profile available for PrusaSlicer, but you can set up Kingroon as Prusa Mini with the same build volume. Since the Prusa Mini is a Bowden style extruder, you only need to lower the retraction value.

Printing with Kingroon KP3S

The KP3S is capable of printing speeds up to 100mm/s, so we printed a high-speed Cali Cat to see how fast it works. The result was a little bumpy in the corners, but not bad overall. Using KingRoon3D, layer height at 100mm/s he sliced to 0.2mm. Jessie Premium Gunmetal Gray PLAPrinting took 47 minutes, about 5 minutes faster than at 60mm/s. Unfortunately, small prints don’t give the printer enough time to reach full speed, but you can see how it handles cornering while running fast.

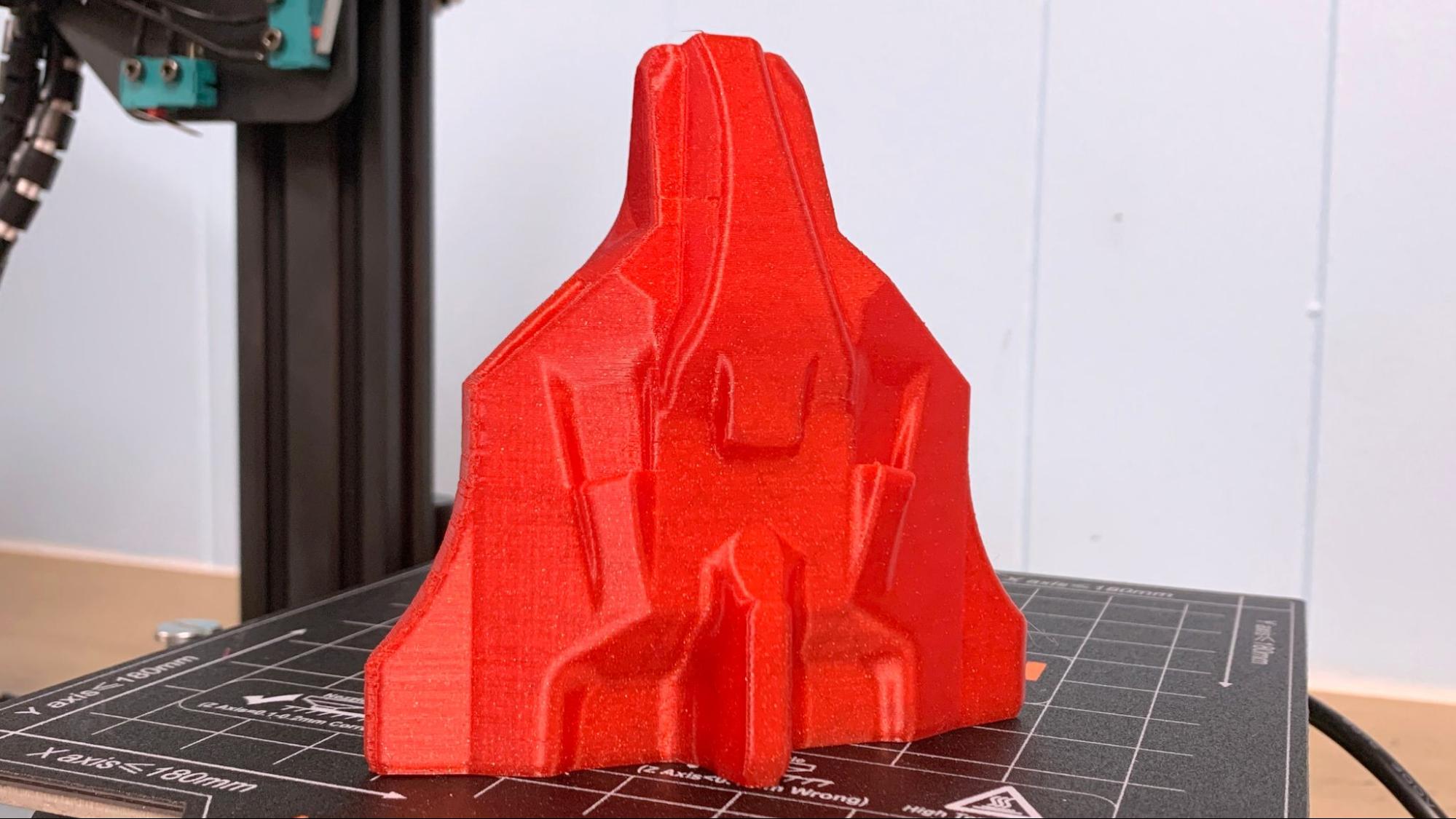

The KP3S isn’t a very big printer, but you’ll be surprised at how much it can actually print. I was able to put these spaceship toys three at a time.These are printed in Atomic Golden Blood Diamond Translucent PLA At a layer height of 0.2 mm and 60 mm/s. With three ships at a time she took 11 hours and 56 minutes.

The PETG also printed smoothly, but there were rough spots where the test print didn’t stick to the bed. This is Clockspring’s Planar Dish, printed flat and then folded slightly to form a shallow bowl.

Print the pedestal separately and fix it with screws to adjust the shape of the bowl. The two parts fit perfectly.printed with Protopasta Candy Apple Red Metallic and Empire Strike Black PETG. Each piece was printed at 60 mm/s with a layer height of 0.2 mm, taking a total of 8 hours and 40 minutes.

The TPU printed fine, but was a bit stringy when trying to run multiple copies at once. this is, RC Death Racer, without any support, printed at a layer height of 0.2mm and a speed of 20mm/s, and took 58 minutes to print.the material is Inland Black TPU (opens in new tab).

Conclusion

Kingroon KP3S is a conundrum for me. On the one hand, it’s very affordable, easy to use, and offers high quality prints. On the other hand, it has an outdated design that wastes space and is inconvenient to move around.

It has a lot of cool features like direct drive, linear rails and a removable build plate with a good stick. However, its clunky tabletop spool holder is hard to align and can cause a few failed prints if the cardboard spool is so light that it literally flies.

Kingroon KP3S is currently not up to the level of the best 3D printers. A more compact Pro version could be more competitive when it releases in December. With a retail price of $169, he’s tempted to buy the KP3S because he knows that a few mods to integrate the printer can fix the design flaw. However, for $159 you get the truly portable Creality Ender 2 Pro. This is our pick for the best compact 3D printer.

more: best 3d printer

more: best resin 3d printer

more: Best filament for 3D printing