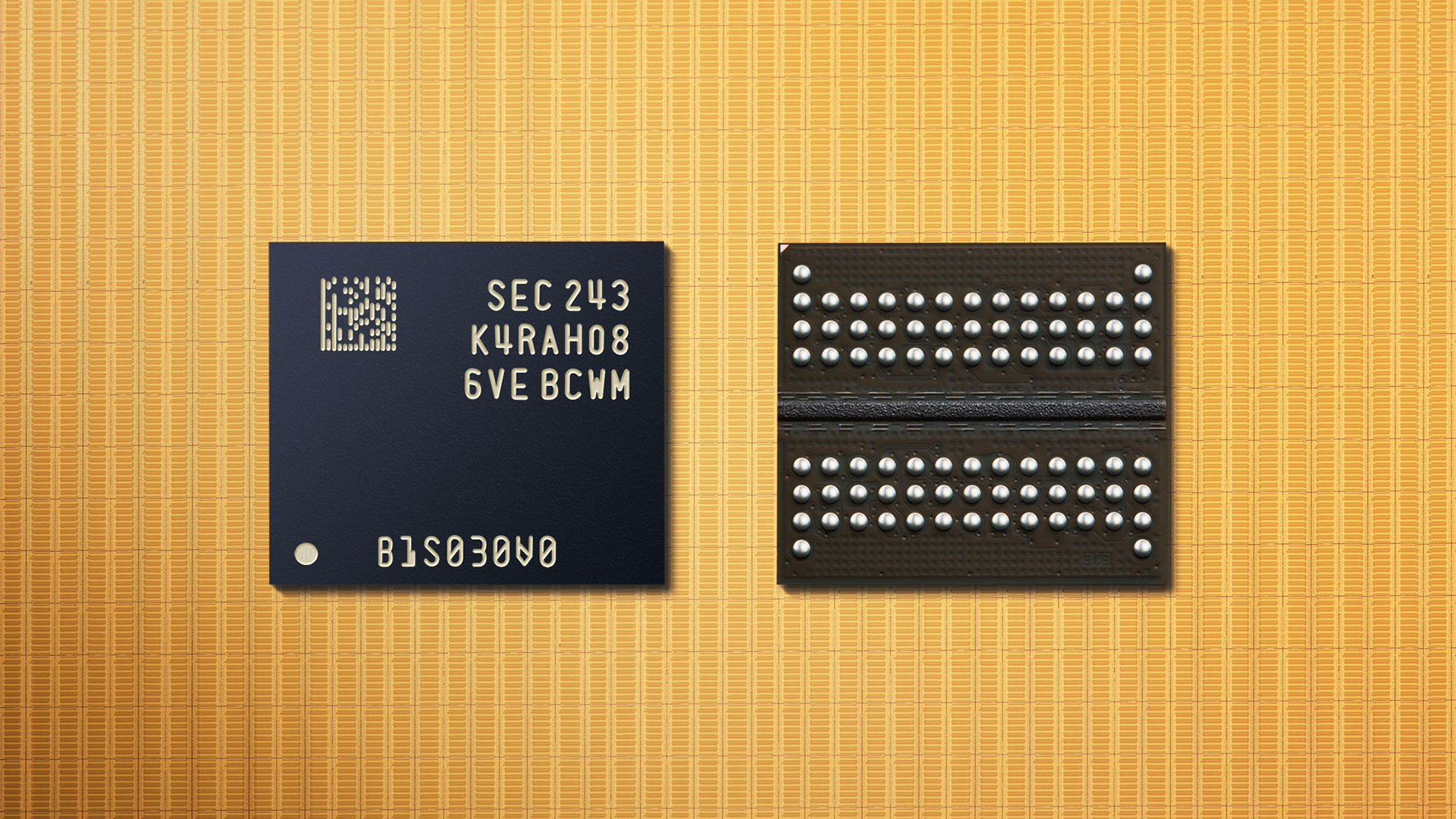

Samsung DDR5-7200 Memory Chips: Small Dies, Extreme Performance

samsung wednesday Said (opens in new tab) The company has developed a new 16Gb DDR5 memory chip featuring data transfer speeds of up to 7200 MT/s. The new ICs are expected to go into mass production next year using the company’s latest he 12nm DRAM process technology. The company is currently validating its latest memory devices with AMD.

In addition to being faster, Samsung’s 16Gb DDR5 memory chips manufactured using the 12nm node are said to consume up to 23% less power than their predecessors (although in which speed bin is unknown). Since it is about 20% smaller than conventional products, it may be cheaper to manufacture.

Increased bit densities and higher default data transfer speeds mean Samsung’s 12nm DRAM process technology will enable the company to manufacture higher density memory ICs and devices with speeds in excess of 7200 MT/s in the future. To do.

Capable of data transfer at up to 7200 MT/s at nominal voltages, memory chips promise to significantly boost the performance of next-generation PCs and enable them to take advantage of them. These ICs also promise to further push the boundaries of enthusiast DDR5 overclocking, so expect even faster DDR5 modules in 2023 and beyond. On the other hand, it’s worth noting that the company is currently validating their latest DDR5-7200 chips with AMD. This could mean that CPU designers plan to support this speed bin sooner or later.

Joe Macri, AMD Senior Vice President, Corporate Fellow, Client, CTO of Computing and Graphics, said: We are delighted to be working with Samsung again, especially regarding the introduction of DDR5 memory products optimized and validated on the “Zen” platform. ”

Today, to get a memory subsystem with a data transfer rate of 7200 MT/s, you usually have to use memory modules or LPDDR5X memory chips made for overclockers that operate at higher than nominal voltages. there is. In the former case, the memory subsystem is power intensive and expensive, while in the latter case it is expensive. Using conventional DDR5-7200 memory chips at nominal voltages can significantly and cheaply increase memory bandwidth.

Samsung’s 12nm production node is the company’s fifth generation 10nm class manufacturing process for DRAM and second generation technology for memory using extreme ultraviolet lithography (EUV). Using multiple his EUV layers will allow Samsung to print circuits faster (i.e. without using multi-patterning) and with greater precision, not only reducing costs but also performance and power. It can lead to increased efficiency. Along with the wider use of EUV, Samsung has also implemented new high-k materials and sophisticated designs of critical circuits.

On the other hand, EUV scanners are significantly more expensive than the deep ultraviolet (DUV) lithography tools used to manufacture memory and logic, so there is no evidence, at least for now, that widespread use of EUV will always drive down DRAM manufacturing costs. is not. Still, we don’t know about Samsung’s production costs, so we’ll leave this part to his DRAM IC analysts.

What’s a bit strange is that Samsung hasn’t revealed exactly when it will start mass-producing its 16Gb DDR5 chips with data transfer speeds of up to 7200 MT/s at the 12nm node. Samsung says he could start mass production in January 2023 or December 2023, so the definition of 2023 is rather vague.

The company appears to lag somewhat behind its peers in the fifth-generation 10nm-class manufacturing process. Micron officially began sampling his LPDDR5X-8500 memory manufactured in his 1β (1-beta) manufacturing technology in early November, but Samsung’s use of his EUV puts the company ahead of its rivals. may also be advantageous.